Laboratory Supplies

Richard Sapp, Missouri State Public Health Laboratory

Laboratory scientist

Laboratory Supplies

Closed-loop recycling program

Impact: statewide

Laboratory Supplies

Laboratory closed-loop plastic recycling program: The Missouri State Public Health Laboratory created supplies by recycling 1,500 pounds of plastic waste

The COVID-19 pandemic brought many disruptions to supply chains across the globe, and the Missouri State Public Health Laboratory (MSPHL) was no stranger to those challenges at a time when testing demand was at an all-time high. The stakes were high. Ultimately, finding a solution in the midst of a global pandemic meant Missourians could rely on testing resources here at home.

The team at the MSPHL knew they needed explore new, outside-of-the-box strategies to replace the much-needed supplies our state needed. MSPHL Laboratory Scientist Richard Sapp had been 3D printing for about a decade personally, becoming adept at running the software and machines required to custom print objects. He had a lightbulb moment: the laboratory could expand and sustain in-house production of laboratory plastic supplies by recycling sterile polypropylene (no.5) waste into raw material for 3D printing supplies.

"We were throwing away about 1,500 pounds of polypropylene (no.5), which is an autoclavable (high-pressure sanitation) plastic, every year," Sapp said. "We endeavored to get equipment that allowed us to convert that 1,500 pounds, of what was functionally trash to us, into something that we could potentially use to assist us in providing testing."

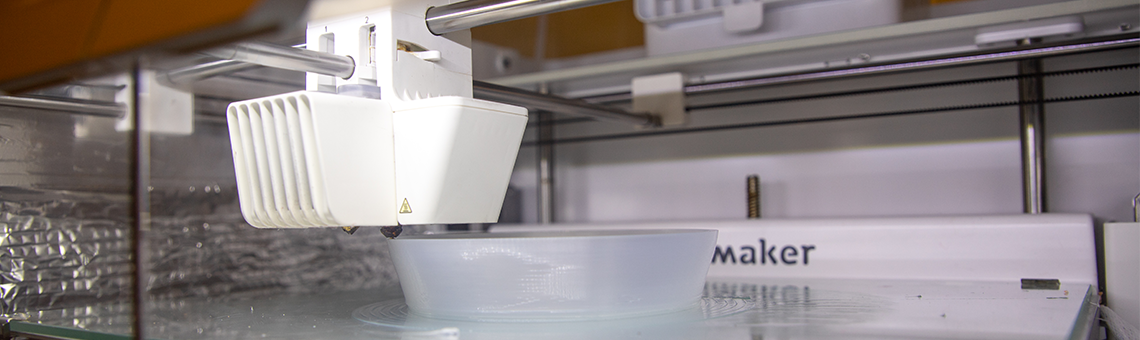

MSPHL enhanced their current technology by purchasing specialized equipment to aid in shredding and grinding the plastic into a refined powder that can be converted into a 3D filament. The 3D filament is used to create supplies critical to the laboratory’s primary functions, i¬ncluding sharps-containers, specimen racks, conical tubes, centrifuge rotors and more. The equipment is allowing the laboratory to implement a closed-loop recycling and reclamation system with the goal of turning sterile waste plastics generated by the lab into new 3D prints. The result is a more self-sufficient and resilient laboratory that Missourians can continue to rely on.

“Every spool that we buy is about 1 pound (about 500 grams), or 2.2 pounds (about 1 kilogram), and half of a 500 gram spool is approximately $75,” Sapp stated. “When you convert it from our 1,500 pounds that are currently waste to 1,500 spools, that’s about $100,000 made back. “

Based on current model projections and current equipment pricing, MSPHL will recover 100% of the initial equipment investment in five years from implementation of the recycling program.